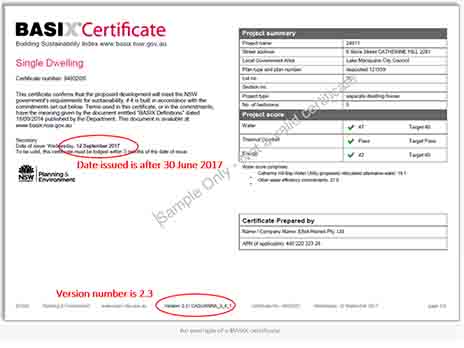

An eco-friendly light steel framing home helps preserve our environment and also saves you money in the long run. Otherwise known as ‘eco-friendly homes’, sustainable homes are becoming increasingly popular worldwide. With minimal impact on our natural resources and lower energy consumption, a sustainable home is one that contributes towards the common goal of reduced carbon emissions. Sustainable design With medium-density dwellings and property developments on the rise, many builders, architects and designers are turning to sustainable practices to offset the effect of urbanisation. In some cases, your designer can use orientation and siting to balance solar access to increase winter warming while avoiding overheating in summer. Design Manager, Mark explains, “By locating areas such as the kitchen, dining and living spaces to the northern side of the house, any north-facing windows and doors can absorb solar gains providing passive heating and better thermal mass, which is great for the winter.” “Alternatively, in the summer, the cooling load can be reduced by placing laundries, bathrooms and garages on the south, east and west-side of the house to shelter it from excess sun and wind.” Mark adds, “Sufficient ventilation is also important, especially during the hotter months. By designing a floor plan with windows strategically placed on both sides of the dwelling, you can get passive cooling effects via cross-ventilation.” Additional methods also include stack ventilation, which can be achieved using double height spaces to ventilate excess solar radiation. Check out the Ashmore 23-C and Hunter 27 designs that feature this technique to passively cool your home. Heating and cooling Australian weather is known to be diverse.To ensure better thermal comfort throughout varying seasons whilst also reducing greenhouse gas from artificial cooling/heating sources, solar panels are incredibly effective. In Kellyville, BuildMart built a multi-dwelling low rise development consisting of 18 unique townhomes, each with solar panels installed. Also considered ‘smart homes’, these Torrens Title houses were estimated to output an average of 25 kwh/day or 9,000.00 kwh/year of solar energy, saving the homeowner $200/month or $2500/year. Some methods can be multi-layered. Recently, we built a home in Baulkham Hills with a polished concrete floor to soak up daytime sun during winter via solar and convert it into a sustainable source of heating. Combined with Hebel wall panels and thicker insulation in the roof, ceiling and walls, the house would achieve ambient warmth when most needed after sunset. Insulation acts as a barrier to the flow of heat, making it essential for keeping your home warm in winter and cool in summer. A well-insulated and well-designed home provides year-round temperature control, cutting cooling and heating bills by up to half. Foil insulation throughout the floors, ceiling, roof and walls can cater for all seasons and in turn, reduces ...

When choosing a metal framing supplier, quality materials are a top priority. That’s why BuildMart steel framing products are manufactured from 100% prime mill certified steel. BuildMart’s products meet customers’ requirements on raw material specification G550, G550 Z275, G550 AZ150. Applications Non-load-bearing exterior curtain walls Axial load-bearing interior and exterior walls Interior non-load-bearing walls Floor joists and headers Rafters, purlins, and girts Metal Framing Sizing Standard Web Sizes 1-5/8″ 2-1/2″ 3-1/2″ 3-5/8″ 4″ 5-1/2″ 6″ 8″ 10″ 12″ 14″ 16″ Flange Sizes 1-1/4″ 1-3/8″ 1-5/8″ 2″ 2-1/2″ 3″ 3-1/2″ Thicknesses and Coatings AISI and ASTM Code Standards AISI’s North American Specification for the Design of Cold-Formed Steel Structural Members A653 – Standard specification for steel sheet, zinc-coated (galvanized) by the hot-dip process A1003 – Standard specification for steel sheet, carbon, and metallic-coated for cold-formed framing members C645 – Standard specification for nonstructural steel framing members C754 – Standard specification for installation of steel framing members to receive screw-attached gypsum panel products C955 – Standard specification for load-bearing (transverse and axial) steel studs, runners (tracks), and bracing or bridging for screw application of gypsum panel products and metal plaster bases E72 – Standard test methods of conducting strength tests of panels for building construction E90 – Standard test method for laboratory measurement of airborne sound transmission loss of building partitions and elements E119 – Standard test methods for fire tests of building construction and materials

By 2030, climate change will make one in 25 Australian homes “uninsurable” if greenhouse gas emissions continue unabated, with riverine flooding posing the greatest insurance risk, a new Climate Council analysis finds. As a professor of architecture, I find this analysis grim, yet unsurprising. One reason is because Australian housing is largely unfit for the challenges of climate change. In the past two years alone we’ve seen over 3,000 homes razed in the 2019-2020 megafires, and over 3,600 homes destroyed in New South Wales Northern Rivers region in the recent floods. Building houses better at withstanding the impacts of climate change is one way we can protect ourselves in the face of future catastrophic conditions. I’m part of a research team that developed a novel, bushfire-resistant house design, which won an international award last month. We hope its ability to withstand fires on its own will encourage owners – who would otherwise stay to defend their home – to flee when bushfires encroach. Let’s take a closer look at the risk of bushfires and why our housing design should one day become a new Australian norm. The house would be made from locally sourced, recycled steel frame trusses. Houses today are easy to burn The Climate Council analysis reveals that across Australia’s 10 electorates most at risk of climate change impacts, one in seven houses will be uninsurable by 2030 under a high emissions scenario. This includes 25,801 properties (27%) in Victoria’s electorate of Nicholls, and 22,274 properties (20%) in Richmond, NSW. Bushfires are among the worsening hazards causing homes to be uninsurable, and pose a particularly high risk to many thousands of homes across eastern Australia. For example, the Climate Council found 55% of properties in the electorate of Macquarie, NSW, will be at risk of bushfires in 2030, if emissions do not fall. This jumps to 64% of properties by 2100. The typical Australian house was not designed with bushfires in mind as most were built decades ago, before bushfire planning and construction regulations came into force. The remains of a house destroyed by a bushfire in Perth, 2021. This means they incorporate burnable materials, such as wood and plasterboard, and have features such as gutters which can trap embers. What’s more, the gaps between building materials are often too large to keep embers out, which means spot fires can start on the inside of the house. And many houses are situated too close to fire-prone grasses and trees. Indeed, at least 90% of houses currently in bushfire zones risk being destroyed in a bushfire. How our new design can withstand fire ? The house has three pavilions that can be built at different times to save cost. The house would be made from BuildMart recycled metal frames. It would be mounted on reinforced concrete pilings to minimise its disturbance on the land, touching the ground only lightly. In this way, we help preserve the site’s biodiversity. The primary building mater...

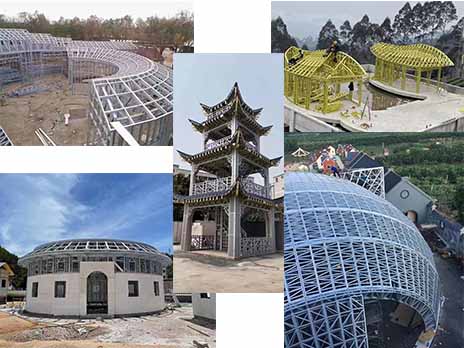

Different buildings can improve the architectural shape of objects, and can make different shapes into Internet celebrity check-in places. The cyclical construction of cities with different architectural forms makes buildings at different times also form a new type of urban short-term construction, which becomes a new type of modern architecture. In the construction of complex and expensive traditional buildings, the light gauge steel structures of traditional buildings can be easily realized. Arc Ceiling Steel Frame Special-Shaped Steel Frame Roof Metal Stud Framing Church Steel Stud Framing Used in tourism Round Metal Stud Ceiling Any interestes or questions, welcome to visit us at www.buildmartmaterial.com.

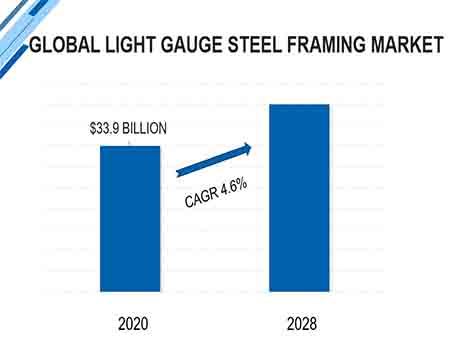

The Global Light Gauge Steel Framing Market size is expected to reach $42. 8 billion by 2028, rising at a market growth of 4.6% CAGR during the forecast period. Users choose low gauge steel frames in current building procedures because they are lighter and recyclable. When compared to typical clay, stone, or brick, it is shown to be cost economical and time-efficient in the construction. Warehouses, office buildings, stadiums, and steel structure workshops are examples of residential and industrial structures that utilize the light steel frame structure system. The worldwide light gauge steel framing market is expected to develop at a faster rate than the global building industry. Over the projected period, the total market is expected to grow due to an increase in construction-related activities in both emerging and developed countries. In the next eight years, numerous housing initiatives established by emerging country governments, like China and India, are likely to promote worldwide market growth. Furthermore, technological advancements have resulted in the production of goods with increased safety, strength, and stability. In concept, light gauge steel framing is quite similar to wood framing. The wooden framework elements are substituted with thin steel parts in steel construction. Cold formed portions are the steel sections utilised in this project. Cold formed steel is created by passing thin layers of steel through a sequence of rollers, each one slightly altering the shape, resulting in a C orU-shaped piece from a flat sheet of steel. The use of light markers reduces the time it takes to produce a product, resulting in increased profits for the company. The advantages associated with the acceptance of light measure steel outlining framework would continue to increase the market. COVID-19 Impact Analysis The World Health Organization has declared a public health emergency after the COVID-19 virus outbreak in December 2019. The disease has spread to over 100 nations and resulted in massive deaths all across the world. Global manufacturing, tourism, and financial sectors have all been heavily damaged. The downward pressure on the global economy, which had previously shown signs of improvement, has escalated once more. The worldwide COVID-19 pandemic, on the other hand, had a substantial influence on market growth in 2020, with some manufacturing businesses reporting a large decline in revenues for the first and second quarters of the year. The market, on the other hand, grew in the later half of Q3 and the beginning of Q4 2020. The industry’s major players are concentrating on extending their market share with mergers and acquisitions. Market Growth Factors: Rising government investments in infrastructure Several governments across developing nations are highly investing in making strong infrastructure, especially in education and healthcare. In addition, the expanding population in these countries is creating more demand for offices, hou...

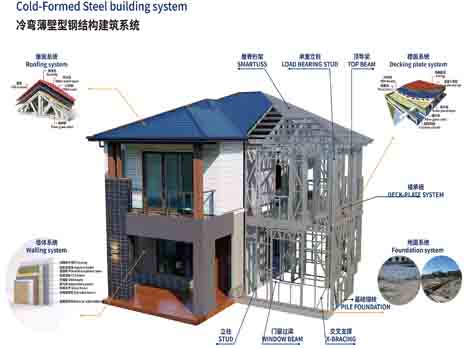

Cold Formed Steel (CFS), also known as light gauge steel (LGS), construction is a practical, code approved solution to many of the limitations that builders face today when using traditional construction materials. Here are five key reasons why CFS construction methods using advanced construction automation systems are superior to traditional building methods. 1. It's faster. Light framing construction is faster than traditional methods, especially during manufacture and construction phases of a project. CFS fabricators supply frames pre-assembled, strong and straight, and clearly identifiable. No on-site welding or cutting is normally required. This means that the erection process is fast and simple. Shorter construction times result in reduced hard costs of build projects. As an example, by building with CFS over traditional heavy materials like concrete and masonry, you can shave 3 months or more off the schedule of a mid-rise project. 2. Highly-skilled on-site labor is not needed. Using highly accurate design and engineering software, pre-engineered steel framing is cut to specified lengths, labeled and pre-dimpled, making assembly simple, fast and accurate. And the only tool needed for assembly is a power drill and provided screws and fasteners. Due to its ease of assembly, less skilled labor is needed on-site, which has obvious bottom-line benefits. 3. It's versatile. The strength and ductility of light gauge or cold formed steel makes it an ideal building material for all building types — from pre-fabricated units to multi-story hotels, hospitals, schools as well as stand-alone, multi-story housing. Cold formed steel is suited to almost any type of building design or application and with one of the highest strength-to-weight ratios of all construction materials, it is possible to produce architectural designs not possible with traditional methods. 4. It offers greater ROI. CFS construction is cost-competitive compared to traditional methods and, depending on the building design, can be cheaper when evaluating the overall build cost due to its advantages in speed of construction, accuracy and reduced labor costs. Cold formed steel construction is also highly scalable, which means it is an ideal solution for mass production and repeatable designs – a huge advantage in areas in need of affordable, quality housing, specifically in developing countries. Long-term building maintenance costs are also reduced as steel is resistant to rot, mold, termite and insect infestation. 5. It's better for the environment. With traditional methods, it is common for builders to factor in up to 20% material wastage in the total cost of a project. Adding this up over consecutive projects, wastage can be equivalent to as much as one building out of every five buildings constructed. But with CFS waste is virtually non-existent (and in the case of a FRAMECAD solution, material wastage is less than 1%). And, steel is 100% recyclable, re...

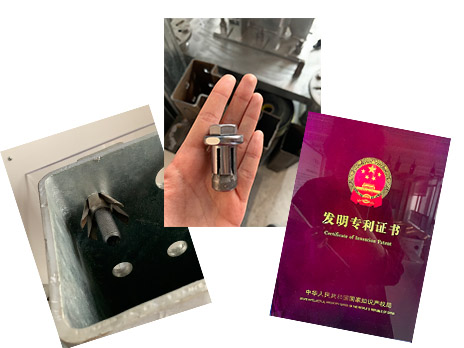

Look at our new product: LGS Bolt used in Light Gauge Steel Structure House • Fast, cost saving installation from one side. • For square, rectangular and circular hollow sections. • High resistance to tensile and shear loads. • High Clamping Force design

The cost of Metal structure villa tends to be cheaper than wood structure house, with an average of $19-25 per sq ft for a steel building and $20-$35 per sq ft for a wood building. Also, using metal in your build has a lower lifetime cost due to near-zero maintenance, and it can be nearly 100% salvaged and sold if it is ever torn down.

Are you debating whether to build a pre-engineered metal building or a wood frame building? Before you decide on this question, you should weigh the advantages and disadvantages of these common building materials. For hundreds of years, people turned to wood for construction because it was familiar and user-friendly. A century ago, wood was easily the best building materials, and there was an abundance of it all over the world. Wood was inexpensive, readily available, and owners could design and build their own structures because the wood was flexible and had a very forgiving erection process. Over the years, though, steel frame construction has become more popular and presents significant advantages over wooden buildings. Because of the several benefits of steel, pre-engineered steel buildings are now the method of choice for most commercial, industrial and warehouse projects. Below we compare how the two materials stack up against each other in a match of wood buildings versus commercial metal buildings.

1

22

pagesCategories

New Products

Easy Installation Waterproof Spc Vinyl Flooring Click Lock System Skirting Read More

3 Stories House Design Heavy and Light Steel Framing Villa Hurricane Resistance Wind Resistant 150mph in Florida USA Read More

China Modern Stable Prefabricated Light Gauge Steel Framing House Easy Installed Read More

Modern Luxury Design 2 Story Prefab Light Steel Villa House Read More

lightweight steel framing House Light Steel Prefab House Read More

Light Steel Frame Structure Design Suit for Residential Home Luxury Villa Hotel Read More

Fully Assembled Modular Light Gauge Steel Framing Villa Read More

Light Steel Frame Prefabricated Steel Building Prefab House Read More

© Copyright 2025 Buildmart (Xiamen) Building Material Technology Co., Ltd.. All Rights Reserved.

IPv6 network supported

Friendly Links:

Scaffold Supplier topvcfloor Mining camp accommodation Cleanroom Turnkey Solution QYT walkie talkie tpmbrickmachine funshinequartzite Steel Structure Buildings Mirror Finish Sheet Prepainted Aluminium Coil Container House Magnetic Separators Aluminum Extrusion Profiles GNSS Receiver Light Steel Structure House